surface grinding machine pdf

The grinding wheel rotates at 3600 rpm has a diameter D of 150 mm thickness b of 25 mm and c 5 grains per mm2. Surface Grinding Machines Surface Grinding Machines is the process of cutting a work piece using a grinding machine.

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece.

. The motor has a power of 2 kW. The material is held in place while the grinding surface moves across or is lowered into the material. The average machinist will be concerned mostly with floor-mounted and bench-mounted utility grinding machines bufting machines.

This system then removes the material to the level of the grinding surface and no further. GMM630 Double Side Surface Grinding Machine. And surface grinding machines.

Cutting tools used in both operations are single-edge cutting tools to create a straight and flat surface. It is essential to give the serial number of your machine in any order of repair parts to assure prompt and accurate service order repair parts by part SN Part. Cylindrical grinding wheel is shown in Figure 21 Type 5.

Combustible liquids must not be used as a cutting liquid. China Surface Grinding Machine Pdf Manufacture Visit Here to Find the Surface Grinding Machine Pdf That You are Searching for. It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use.

The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following. The machine should not be used to grind lumber plastic or other combustible materials. Universal cylindrical surface grinder 3.

Generally the grinding is finishing operation to show the high surface quality accuracy of the shape and dimension. 234 Cup Wheel Cup wheel shown in Figure 21 Type 6. Grinding energy u of 35 W-smm3.

Grinding are the material of the grinding wheel and the material of the piece being worked on. From the simplest grinding machine to the most complex grinding machines can be classified as utility grinding machines cylindrical grinding machines. For sharpening miscellananeus cutters a universal type grinder is used.

The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot. The work piece moves v at 15 mmin. The machine must not be installed in areas with explosive materials.

Other materials are aluminium stainless steel brass and some plastics. These two materials dont tend to clog the grinding wheel while being processed. Creep feed grinding is an adaptation of surface grinding which introduces a moving stock material into the path of a rotating abrasive wheel.

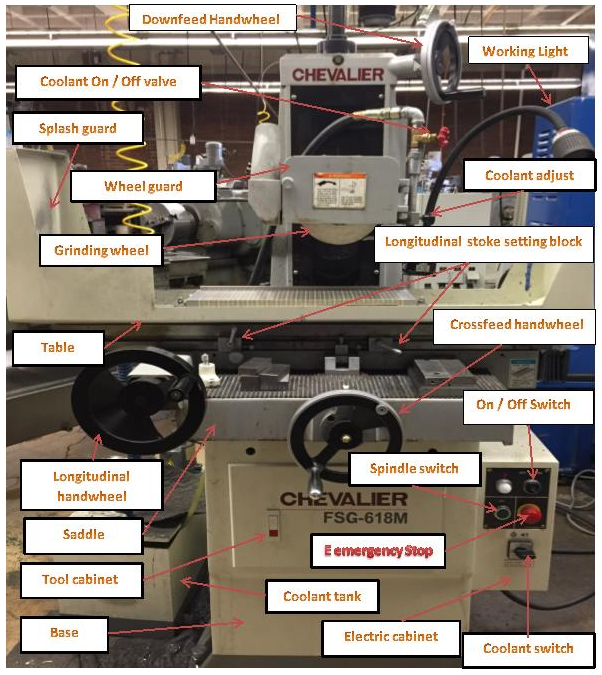

Introduction of Surface Grinding Machine. FOR SURFACE GRINDER. These machines are limited to low speeds due to their start-.

2 -- Specification and parameters of surface grinders Model M618A Table Size inch 18-7647-332 Max. Cylindrical grinding machine This machine is used to produce external cylindrical surface. Plain centre type cylindrical grinder 2.

The chip thickness ratio r is 10. There are four different types of surface grinders. It is used for surface grinding ie.

Interrupted cutting occurs in them subjecting the tool to an impact loading upon entry into the work. Grinding takes place with the help of face of the wheel. And reciprocating surface.

Table travel inch 19-11167-3164 Max. 13During wet grindingthe nozzles cannot be adjusted when the wheel spindle is rotating. 14When the work table is in motion or when the wheel spindle is rotatingthe work piece can not be moved or changed.

What can I do for you. Determine the. Surface Grinding Machine - View presentation slides online.

12When grindingbesides securely mounting the work pieceone should make sure no other object is placed on the machine. A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish correct size and accurate shape of the workpiece. Surfaces may be straight tapered steps or profiled.

Shaping Planning Machines Shaping and planning are similar operations. The basic machine has a grinding wheel above the work area which can be fed downward in very small increments into a work piece which is being moved to the left and the right and in and out. Last review 02 March 2011 UofS Mech.

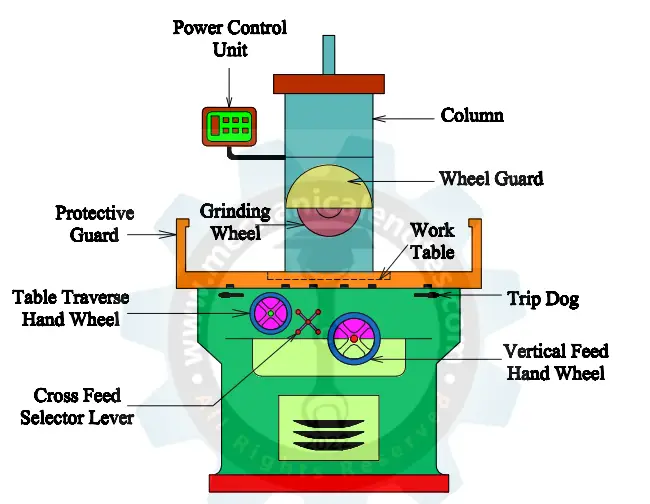

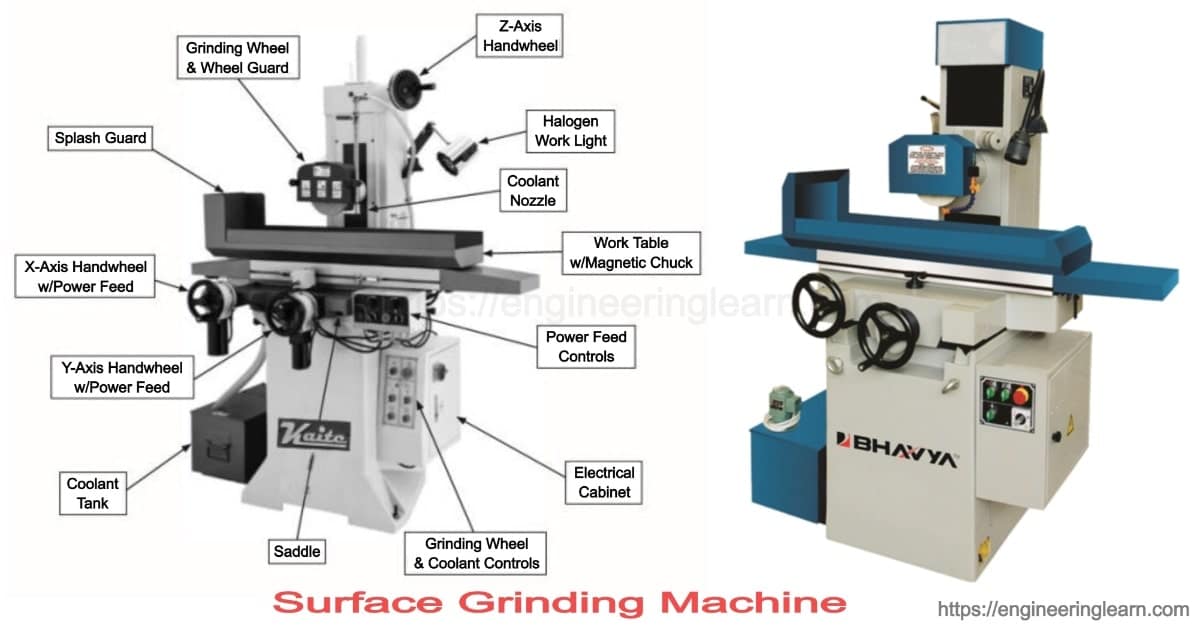

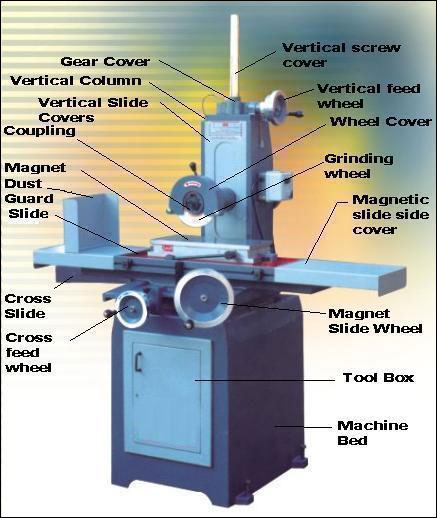

Precision Surface Grinding Machine Precision Surface Grinding Machine and Technology 0506 7HFK UHVHUYHV WKH ULJKW WR FKDQJH VSHFLILFDWLRQV DQG GHVLJQ FKDUDFWHULVWLFV ZLWKRXW SULRU QRWLFH Standard accessories K v o 2 Axes Crossfeed Set Up Grinding Cycle 1. Horizontal spindle and reciprocating table type 2. In operation the work piece is held or held on a magnetic table that is moved forward and backward or rotates under a rotating grinding wheel Function Of Flat Grinding Machines.

Types of Grinding wheels. Types of surface grinding machines Tool and cutter grinder In grinding tools by hand a bench or pedastal type of grinder is used. Wet grinding material that produce dust during the grinding process.

235 Flaring Cup Wheel. Study of Machine Tools Grinding Machines Page 2 424 Surface grinding machines Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle. Typical work piece materials include cast iron and mild steel.

Determine the grinding force and force per grain. What Is Surface Grinding Machines. Production of flat surfaces.

Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material. It is used for grinding flat surfaces with the help of face of grinding wheel. Steinmetz SAFETY OPERATING PROCEDURES Surface Grinder - Elliott Victoria DO NOT use this surface grinder unless you received training by a.

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial. This allows the wheel to contact all areas of the surface of the work piece. Centreless cylindrical surface.

Broadly there are three different types of cylindrical grinding machine as follows.

Pin On Machine Design Miscellaneous Tools

2x72 Belt Grinder Plans Dxf Files Included Kopo Etsy Belt Grinder Plans 2x72 Belt Grinder Plans Belt Grinder

Chapter 5 Surface Grinder Manufacturing Processes 4 5

Surface Grinding Machine Saddle Type Manual Seedtec Machinery Co Ltd

Acto Tool Cutter Grinder Plans Machinery Plans Metal Working Tools Lathe Tools Milling Machine Projects

Belt Small Grinder Plans And Dxf Files Building Info And 3d Etsy Belt Grinder Plans Belt Grinder 2x72 Belt Grinder Plans

Surface Grinding Machine Types Parts Working Procedure Engineering Learn

Sga 1 Surface Grinding Attachment For Kmg Wuertz Machine Works Belt Grinder Plans Belt Grinder Knife Making

Inch Plans Gen 2 Tilting Belt Grinder Etsy Espana Lijadora De Banda Casera Lijadoras Microsoft

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

Machine Tool Practices 10th Edition Diy Books Machine Tools Pdf Books Free Books Online

14 Types Of Grinding Machines Working Diagram Pdf

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

2x72 Tilting Belt Grinder Plans A Set Of Comprehensive Files Etsy In 2021 Belt Grinder Plans Belt Grinder 2x72 Belt Grinder Plans

8 Types Of Grinding Machine Parts Working Principle Grinding Wheel Complete Details Engineering Learn

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

2x72 Belt Sander Grinder Machine Ce Certification Etsy

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram